PriceList for Horizontal Concentric Taping Machine - Horizontal Taping Machine-Single Conductor PengSheng

PriceList for Horizontal Concentric Taping Machine - Horizontal Taping Machine-Single Conductor PengSheng Detail:

Main technical data

Conductor area: 5 mm²—120mm²(or customized)

Covering layer: 2 or 4 times of layers

Rotating speed: max. 1000 rpm

Line speed: max. 30 m/min.

Pitch accuracy: ±0.05 mm

Taping pitch: 4~40 mm, step less adjustable

Special Characteristics

-Servo drive for the taping head

-Rigid and modular structure design to eliminate vibration interaction

-Taping pitch and speed easy adjusted by touch screen

-PLC control and touch screen operation

Overview

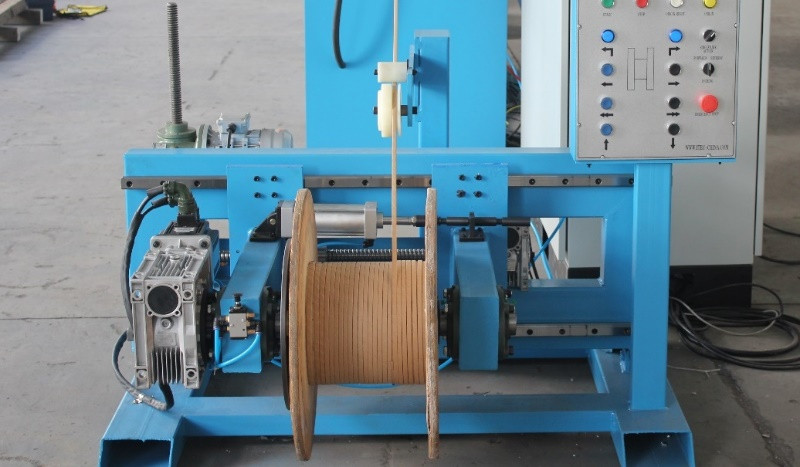

Taping head

Caterpillar

Take-up

Product detail pictures:

Related Product Guide:

Quality First,and Customer Supreme is our guideline to provide the best service to our customers.Nowadays, we are trying our best to become one of the best exporters in our field to meet customers more need for PriceList for Horizontal Concentric Taping Machine - Horizontal Taping Machine-Single Conductor PengSheng , The product will supply to all over the world, such as: Bangladesh, Libya, Ghana, We are proud to supply our products and solutions to every costumer all around the world with our flexible, fast efficient services and strictest quality control standard which has always approved and praised by customers.

The factory has advanced equipment, experienced staffs and good management level, so product quality had assurance, this cooperation is very relaxed and happy!

Write your message here and send it to us