Products

-

High Quality Coiler/Barrel Coiler

• easy for use in the rod breakdown machine and intermediate drawing machine line

• suitable for barrels and cardboard barrels

• eccentric rotating unit design for coiling wire with rosette pattern laying, and trouble-free downstream processing -

Automatic Double Spooler with Fully Automatic Spool Changing System

• double spooler design and fully automatic spool changing system for continuous operation

• three-phase AC drive system and individual motor for wire traversing

• adjustable pintle-type spooler, wide range of spool size could be used -

Compact Design Dynamic Single Spooler

• compact design

• adjustable pintle-type spooler, wide range of spool size could be used

• double spool lock structure for spool running safety

• traverse controlled by inverter -

Single Spooler in Portal Design

• specially designed for compact wire winding, suitable for equipping in rod breakdown machine or rewinding line

• individual touch screen and PLC system

• hydraulic control design for spool loading and clamping -

Continuous Extrusion Machinery

The continuous extrusion technical is a revolutionary in the line of non-ferrous metal processing, it is used for a wide range of copper, aluminum or copper alloy rod extrusion to mainly make a variety of flat, round, bus bar, and profiled conductors, etc.

-

Continuous Cladding Machinery

Applying for aluminum cladding steel wire (ACS wire), Aluminum sheath for OPGW, communication cable,CATV,coaxial cable,etc.

-

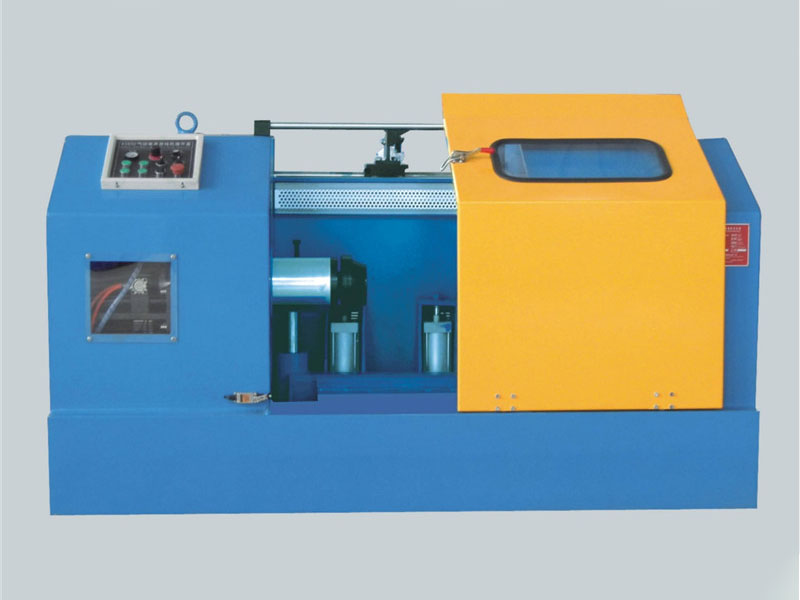

Horizontal Taping Machine-Single Conductor

Horizontal taping machine is used to make insulating conductors. This machine is suitable for tapes made of different materials, such as paper, polyester, NOMEX and mica. With years of experience on horizontal taping machine design and manufacturing, we developed the latest tapping machine with characters of high quality and high rotating speed up to 1000 rpm.

-

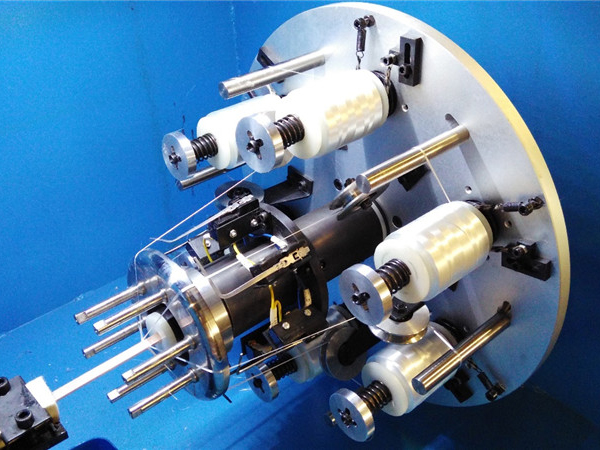

Combined Taping Machine – Multi Conductors

Combined taping machine for multi-conductors is our continuous development on horizontal taping machine for single conductor. 2,3 or 4 taping units could be customized in one combined cabinet. Each conductor simultaneously goes through taping unit and is taped respectively in the combined cabinet, then the taped conductors are gathered and taped to be one combined conductor.

-

Douglas Fiberglass Taping Machine for Wire Insulating

Douglas fiberglass taping machine is designed to insulate round or flat conductors by applying Douglas fiberglass materials. Combination of wrapping conductors with thermal sintering process by high frequency inductor and oven, so that the good and consistent product will be made.

-

Fiber Glass Insulating Machine

The machine is designed to produce fiberglass insulating conductors. Fiber glass yarns are winded to conductor firstly and insulating varnish is applied subsequently, then the conductor will be solidly combined by radiant oven heating. The design complies with market requirements and adopts our long-lasting experience in the field of fiberglass insulating machine.

-

PI Film/Kapton® Taping Machine

Kapton® taping machine is designed specially to insulate round or flat conductors by applying Kapton® tape. Combination of taping conductors with thermal sintering process by heating the conductor from inside (IGBT induction heating) as well as from outside (Radiant oven heating), so that the good and consistent product will be made.

-

Double Twist Bunching Machine

Bunching/Stranding Machine for Wire and Cable Bunching/stranding machines are designed for twisting wires and cables to be a bunch or a strand. For different wire and cable structure, our different models of double twist bunching machine and single twist bunching machine support well for most kinds of needs.