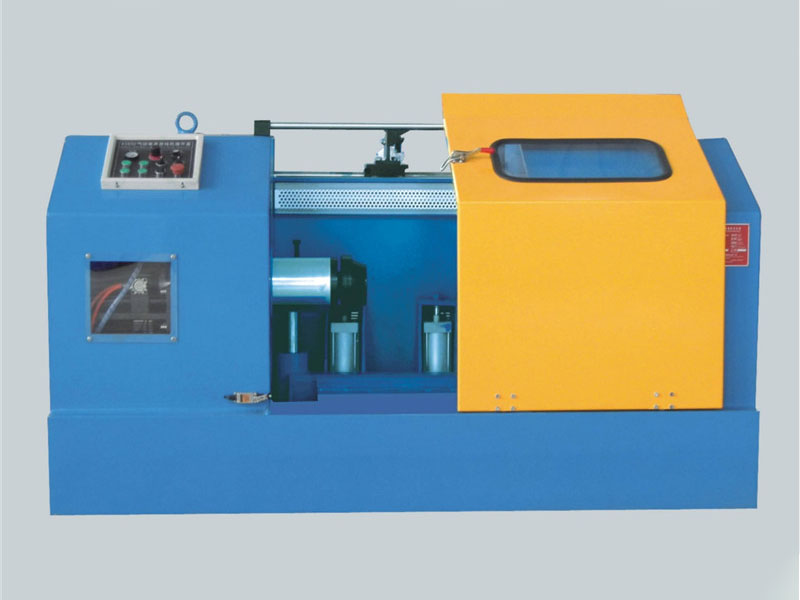

Professional China Aluminum Continuous Casting Machine - Compact Design Dynamic Single Spooler PengSheng

Professional China Aluminum Continuous Casting Machine - Compact Design Dynamic Single Spooler PengSheng Detail:

Productivity

• double air cylinder for spool loading, un-loading and lifting, friendly to operator.

Efficiency

• suitable for single wire and multiwire bundle, flexible application.

• various protection minimizes failure occurrence and maintenance.

| Type | WS630 | WS800 |

| Max. speed [m/sec] | 30 | 30 |

| Inlet Ø range [mm] | 0.4-3.5 | 0.4-3.5 |

| Max. spool flange dia. (mm) | 630 | 800 |

| Min barrel dia. (mm) | 280 | 280 |

| Min bore dia. (mm) | 56 | 56 |

| Motor power (kw) | 15 | 30 |

| Machine size(L*W*H) (m) | 2*1.3*1.1 | 2.5*1.6*1.1 |

| Weight (kg) | Approx1,900 | Approx3,500 |

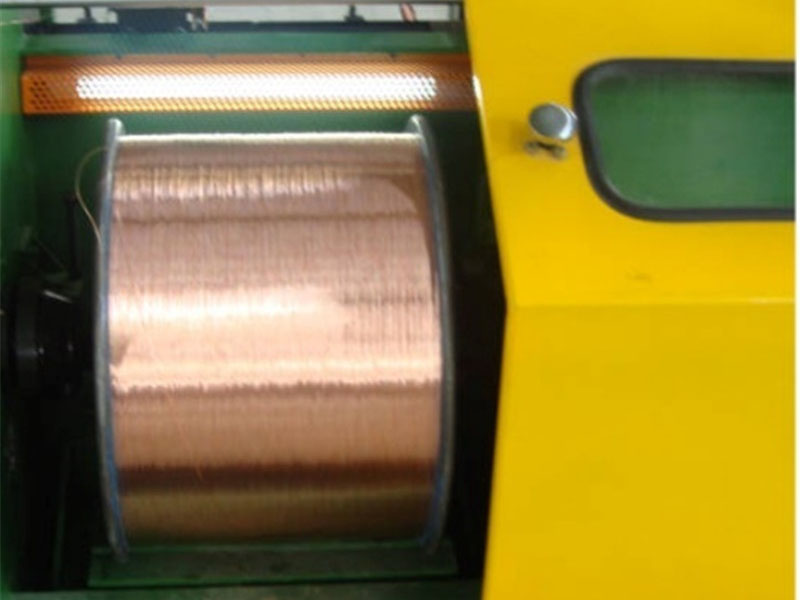

Product detail pictures:

Related Product Guide:

"Based on domestic market and expand overseas business" is our development strategy for Professional China Aluminum Continuous Casting Machine - Compact Design Dynamic Single Spooler PengSheng , The product will supply to all over the world, such as: Finland, Slovakia, Liverpool, We are adhering to the philosophy of "attracting customers with the best products and excellent service". We welcome customers, business associations and friends from all parts of the world to contact us and seek cooperation for mutual benefits.

We are a small company that has just started, but we get the company leader's attention and gave us a lot of help. Hope we can make progress together!

Write your message here and send it to us