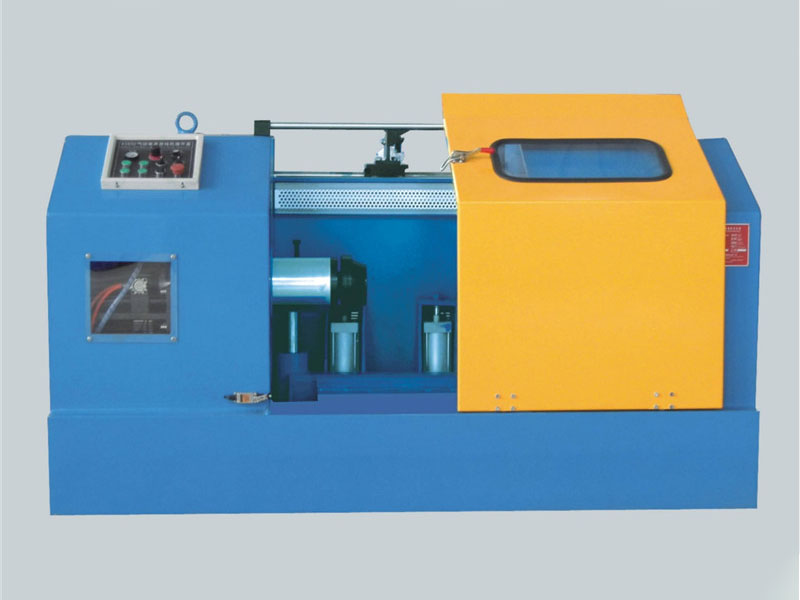

Professional China Aluminum Continuous Casting Machine - Compact Design Dynamic Single Spooler PengSheng

Professional China Aluminum Continuous Casting Machine - Compact Design Dynamic Single Spooler PengSheng Detail:

Productivity

• double air cylinder for spool loading, un-loading and lifting, friendly to operator.

Efficiency

• suitable for single wire and multiwire bundle, flexible application.

• various protection minimizes failure occurrence and maintenance.

| Type | WS630 | WS800 |

| Max. speed [m/sec] | 30 | 30 |

| Inlet Ø range [mm] | 0.4-3.5 | 0.4-3.5 |

| Max. spool flange dia. (mm) | 630 | 800 |

| Min barrel dia. (mm) | 280 | 280 |

| Min bore dia. (mm) | 56 | 56 |

| Motor power (kw) | 15 | 30 |

| Machine size(L*W*H) (m) | 2*1.3*1.1 | 2.5*1.6*1.1 |

| Weight (kg) | Approx1,900 | Approx3,500 |

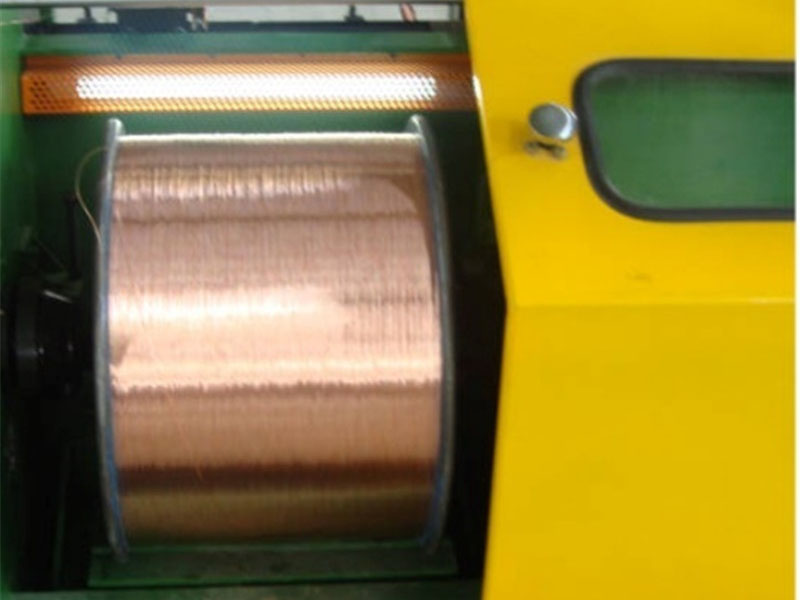

Product detail pictures:

Related Product Guide:

We not only will try our greatest to offer you excellent services to each individual client, but also are ready to receive any suggestion offered by our buyers for Professional China Aluminum Continuous Casting Machine - Compact Design Dynamic Single Spooler PengSheng , The product will supply to all over the world, such as: venezuela, Florence, Uganda, We welcome you to visit our company & factory and our showroom displays various products and solutions that will meet your expectations. Meanwhile, it is convenient to visit our website. Our sales staff will try their best to supply you with the best services. If you will need more information, please do not hesitate to contact us via E-mail, fax or telephone.

The company comply with the contract strict, a very reputable manufacturers, worthy a long-term cooperation.

Write your message here and send it to us