Professional China Conductor Taping Machines - PI Film/Kapton® Taping Machine PengSheng

Professional China Conductor Taping Machines - PI Film/Kapton® Taping Machine PengSheng Detail:

Main technical data

Round conductor diameter: 2.5mm—6.0mm

Flat conductor area: 5 mm²—80 mm²(Width: 4mm-16mm, Thickness: 0.8mm-5.0mm)

Rotating speed: max. 1500 rpm

Line speed: max. 12 m/min

Special Characteristics

-Servo drive for the concentric tapping head

-IGBT induction heater and moving radiant oven

-Auto-stop when film broken

-PLC control and touch screen operation

Overview

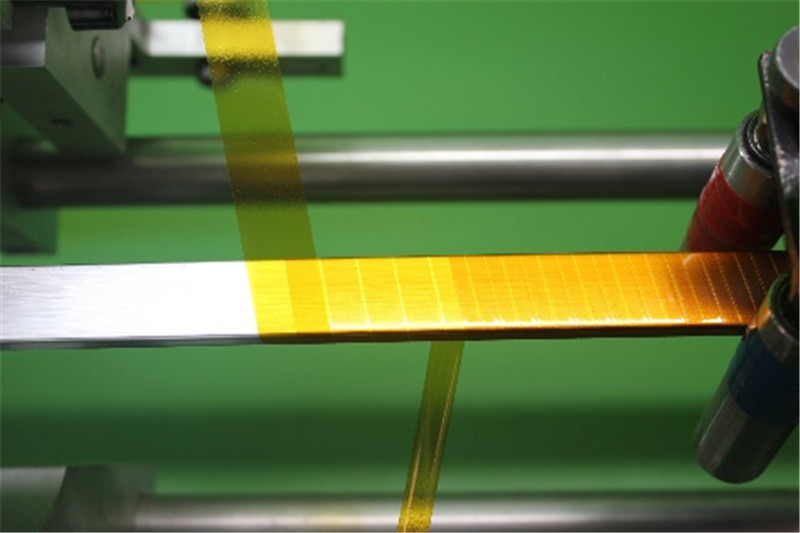

Taping

IGBT Induction heater

Radiant oven

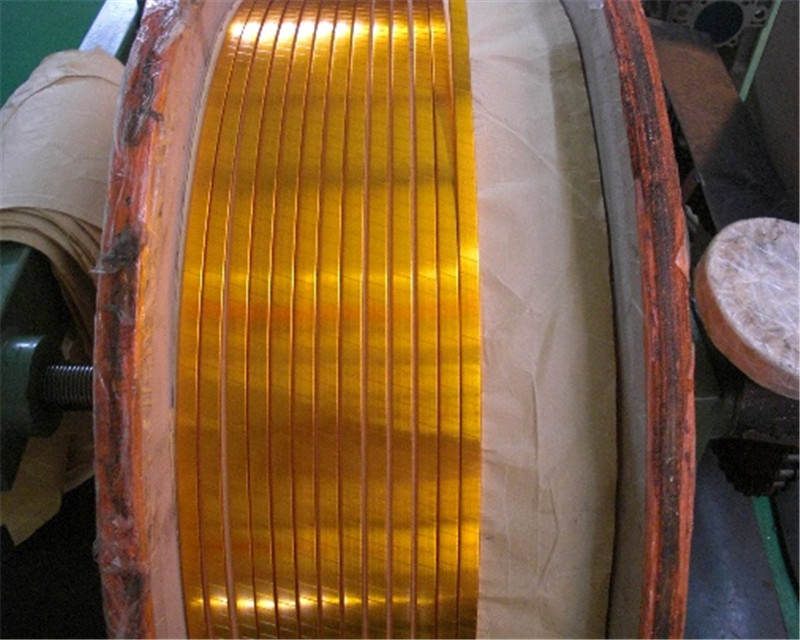

Take-up

Product

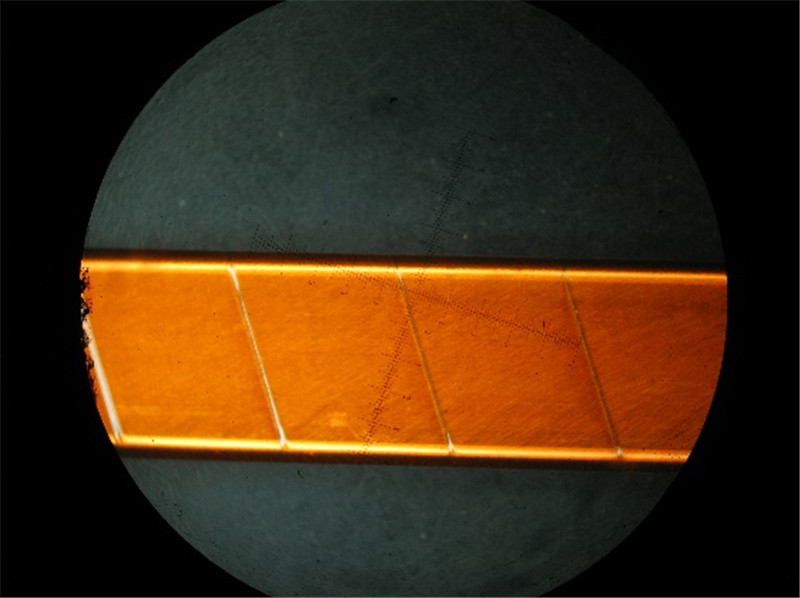

Product detail pictures:

Related Product Guide:

Our firm promises all consumers with the first-class products as well as most satisfying post-sale services. We warmly welcome our regular and new consumers to join us for Professional China Conductor Taping Machines - PI Film/Kapton® Taping Machine PengSheng , The product will supply to all over the world, such as: Auckland, Canada, Croatia, As a way to use the resource on the expanding info in international trade, we welcome prospects from everywhere on the web and offline. In spite on the high quality items we offer, effective and satisfying consultation service is supplied by our qualified after-sale service group. Item lists and detailed parameters and any other info weil be sent to you timely for the inquiries. So please make contact with us by sending us emails or call us when you've got any questions about our organization. ou could also get our address information from our site and come to our enterprise. We get a field survey of our merchandise. We are confident that we'll share mutual accomplishment and create solid co-operation relations with our companions within this market place. We're seeking forward for your inquiries.

Product quality is good, quality assurance system is complete, every link can inquire and solve the problem timely!

Write your message here and send it to us