Reasonable price Flux Cored Welding Wire Forming Machine - Flux Cored Welding Wire Production Line PengSheng

Reasonable price Flux Cored Welding Wire Forming Machine - Flux Cored Welding Wire Production Line PengSheng Detail:

The line is composed by following machines

● Strip pay-off

● Strip surface cleaning unit

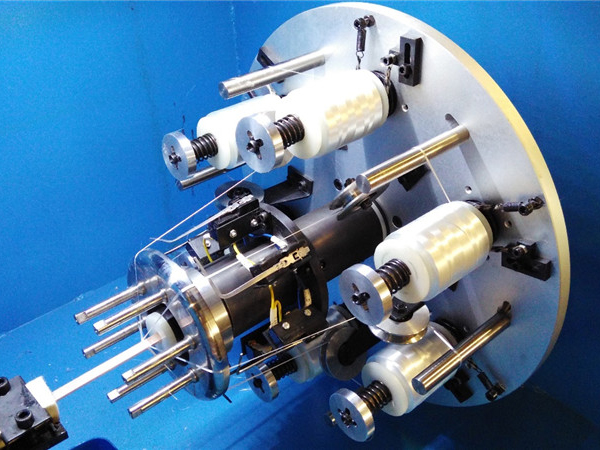

● Forming machine with powder feeding system

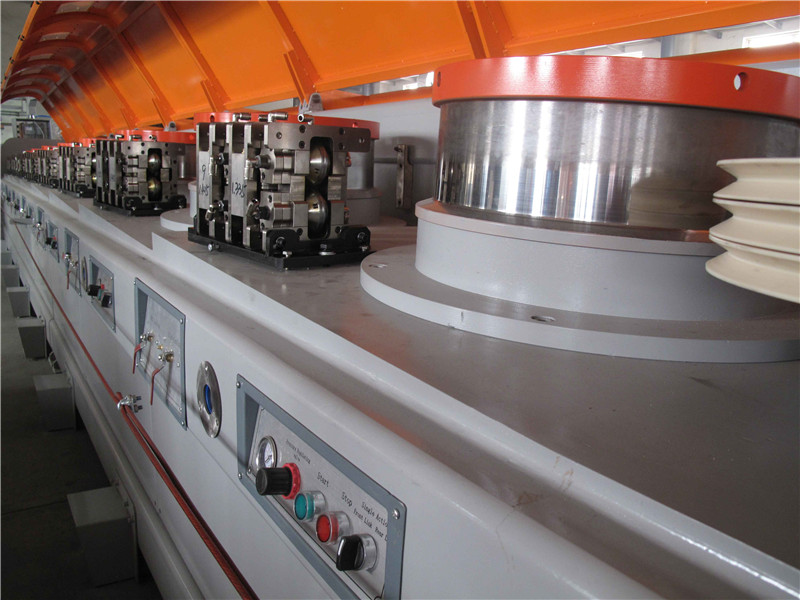

● Rough drawing and fine drawing machine

● Wire surface cleaning and oiling machine

● Spool take-up

● Layer rewinder

Main technical specifications

|

Steel strip material |

Low carbon steel, stainless steel |

|

Steel strip width |

8-18mm |

|

Steel tape thickness |

0.3-1.0mm |

|

Feeding speed |

70-100m/min |

|

Flux filling accuracy |

±0.5% |

|

Final drawn wire size |

1.0-1.6mm or as customer required |

|

Drawing line speed |

Max. 20m/s |

|

Motor/PLC/Electrical elements |

SIEMENS/ABB |

|

Pneumatic parts/Bearings |

FESTO/NSK |

Product detail pictures:

Related Product Guide:

Bear "Customer initially, High-quality first" in mind, we work closely with our prospects and supply them with efficient and specialist companies for Reasonable price Flux Cored Welding Wire Forming Machine - Flux Cored Welding Wire Production Line PengSheng , The product will supply to all over the world, such as: Salt Lake City, Amsterdam, Nicaragua, With strong technical strength and advanced production equipment, and SMS people purposefully , professional, dedicated spirit of enterprise. Enterprises took the lead through the ISO 9001:2008 international quality management system certification, CE certification EU ; CCC.SGS.CQC other related product certification. We look forward to reactivating our company connection.

Factory equipment is advanced in the industry and the product is fine workmanship, moreover the price is very cheap, value for money!

Write your message here and send it to us