Reliable Supplier Steel Wire Hot Dip Galvanizing Process Line - Dry Steel Wire Drawing Machine PengSheng

Reliable Supplier Steel Wire Hot Dip Galvanizing Process Line - Dry Steel Wire Drawing Machine PengSheng Detail:

Features

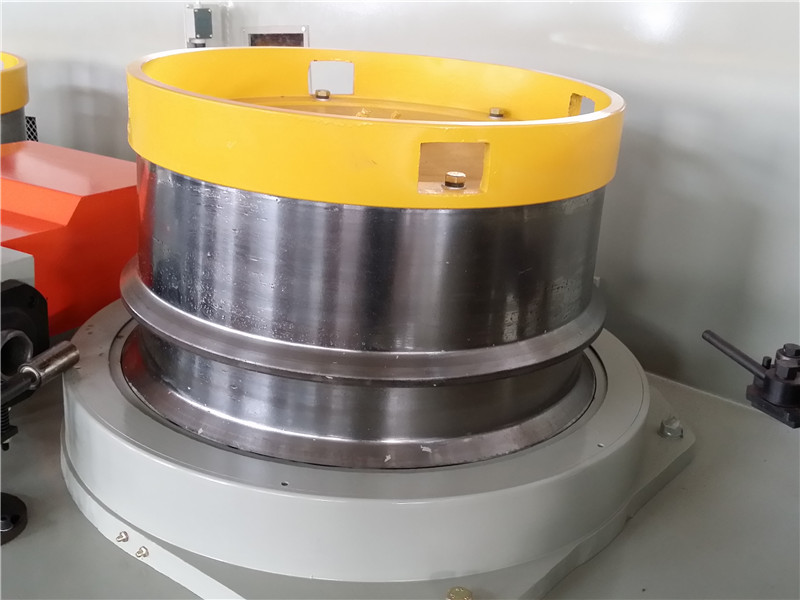

● Forged or casted capstan with hardness of HRC 58-62.

● High efficiency transmission with gear box or belt.

● Movable die box for easy adjustment and easy die changing.

● High performance cooling system for the capstan and die box

● High safety standard and friendly HMI control system

Available options

● Rotating die box with soap stirrers or rolling cassette

● Forged capstan and tungsten carbide coated capstan

● Accumulation of first drawing blocks

● Block stripper for coiling

● First level international electrical elements

Main technical specifications

|

Item |

LZn/350 |

LZn/450 |

LZn/560 |

LZn/700 |

LZn/900 |

LZn/1200 |

|

Drawing Capstan |

350 |

450 |

560 |

700 |

900 |

1200 |

|

Max. Inlet Wire Dia.(mm) |

4.3 |

5.0 |

7.5 |

13 |

15 |

20 |

|

Max. Inlet Wire Dia.(mm) |

3.5 |

4.0 |

6.0 |

9 |

21 |

26 |

|

Min. Outlet Wire Dia.(mm) |

0.3 |

0.5 |

0.8 |

1.5 |

2.4 |

2.8 |

|

Max. Working Speed(m/s) |

30 |

26 |

20 |

16 |

10 |

12 |

|

Motor Power(KW) |

11-18.5 |

11-22 |

22-45 |

37-75 |

75-110 |

90-132 |

|

Speed Control |

AC variable frequency speed control |

|||||

|

Noise Level |

Less than 80 dB |

|||||

Product detail pictures:

Related Product Guide:

We can easily usually fulfill our respected customers with our very good top quality, very good price tag and excellent support due to we have been more expert and much more hard-working and do it in cost-effective way for Reliable Supplier Steel Wire Hot Dip Galvanizing Process Line - Dry Steel Wire Drawing Machine PengSheng , The product will supply to all over the world, such as: Brunei, Accra, Armenia, We strongly believe that technology and service is our base today and quality will create our reliable walls of future. Only we've got better and better quality , could we achieve our customers and ourselves, too. Welcome customers all over the word to contact us for getting further business and reliable relationships. We have been always here working for your demands whenever you require.

The goods are very perfect and the company sales manager is warmful, we will come to this company to purchase next time.