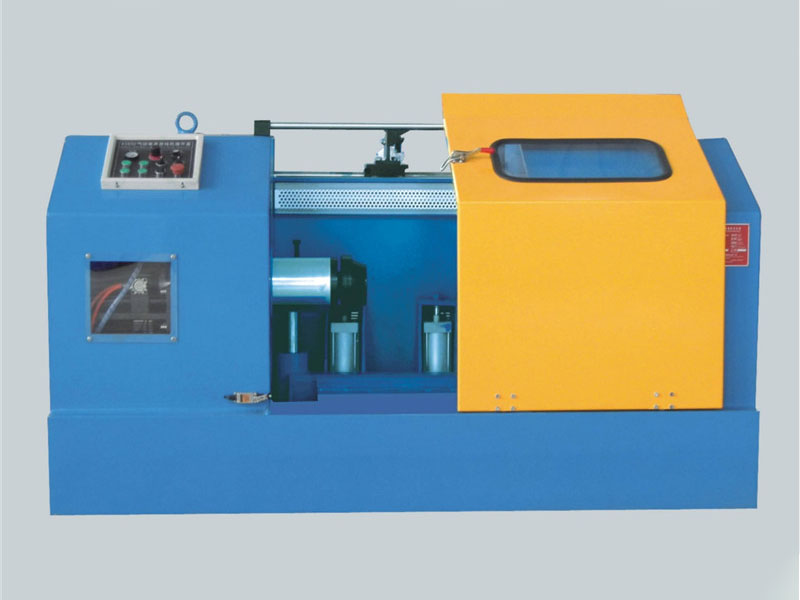

Rod Breakdown Machine with Individual Drives

Productivity

• touchscreen display and control, high automatic operation

• quick drawing die change system and elongation to each die is adjustable for easy operation and high speed running

• single or double wire path design to meet different production requirements

• greatly reduces the generation of slip in the drawing process, microslip or no-slip makes the finished products with good quality

Efficiency

• suitable for variety of non-ferrous metals, copper, aluminum, aluminum alloy, brass, etc.

• individual servo system for easy operation and maintenance

• force cooling/ lubrication system and sufficient protection technology for machine to guarantee machine with long service life

• automatic program of drawing power output against wire outlet size, energy saving

Main technical data

| Type | WDL | WZL |

| Max inlet Ø [mm] | 8 | 4 |

| Outlet Ø range [mm] | 1.2-3.5 | 0.32-2.76 |

| No. of wires | 1/2 | 1/2 |

| Max. speed [m/sec] | 30 | 33.3 |

| Wire elongation per draft | 8-48% |