Short Lead Time for Tubular Steel Wire Stranding Machine - Dry Steel Wire Drawing Machine PengSheng

Short Lead Time for Tubular Steel Wire Stranding Machine - Dry Steel Wire Drawing Machine PengSheng Detail:

Features

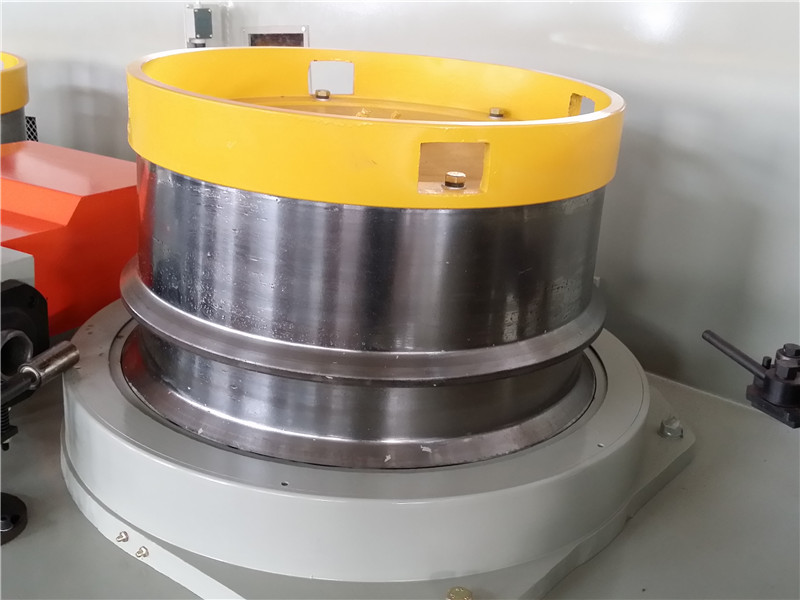

● Forged or casted capstan with hardness of HRC 58-62.

● High efficiency transmission with gear box or belt.

● Movable die box for easy adjustment and easy die changing.

● High performance cooling system for the capstan and die box

● High safety standard and friendly HMI control system

Available options

● Rotating die box with soap stirrers or rolling cassette

● Forged capstan and tungsten carbide coated capstan

● Accumulation of first drawing blocks

● Block stripper for coiling

● First level international electrical elements

Main technical specifications

|

Item |

LZn/350 |

LZn/450 |

LZn/560 |

LZn/700 |

LZn/900 |

LZn/1200 |

|

Drawing Capstan |

350 |

450 |

560 |

700 |

900 |

1200 |

|

Max. Inlet Wire Dia.(mm) |

4.3 |

5.0 |

7.5 |

13 |

15 |

20 |

|

Max. Inlet Wire Dia.(mm) |

3.5 |

4.0 |

6.0 |

9 |

21 |

26 |

|

Min. Outlet Wire Dia.(mm) |

0.3 |

0.5 |

0.8 |

1.5 |

2.4 |

2.8 |

|

Max. Working Speed(m/s) |

30 |

26 |

20 |

16 |

10 |

12 |

|

Motor Power(KW) |

11-18.5 |

11-22 |

22-45 |

37-75 |

75-110 |

90-132 |

|

Speed Control |

AC variable frequency speed control |

|||||

|

Noise Level |

Less than 80 dB |

|||||

Product detail pictures:

Related Product Guide:

Our aim would be to fulfill our shoppers by offering golden company, very good value and good quality for Short Lead Time for Tubular Steel Wire Stranding Machine - Dry Steel Wire Drawing Machine PengSheng , The product will supply to all over the world, such as: Palestine, Victoria, Zurich, We also provide OEM service that caters to your specific needs and requirements. With a strong team of experienced engineers in hose design and development, we value every opportunity to provide best products for our customers.

High production efficiency and good product quality, fast delivery and completed after-sale protection, a right choice, a best choice.