Super Lowest Price Wire Strand Processing Line - Prestressed Concrete (PC) Bow Skip Stranding Line PengSheng

Super Lowest Price Wire Strand Processing Line - Prestressed Concrete (PC) Bow Skip Stranding Line PengSheng Detail:

● Bow skip type strander to produce international standard strands.

● Double couple of pulling capstan up to 16 tons force.

● Movable induction furnace for wire thermo mechanical stabilization

● High efficiency water tank for wire cooling

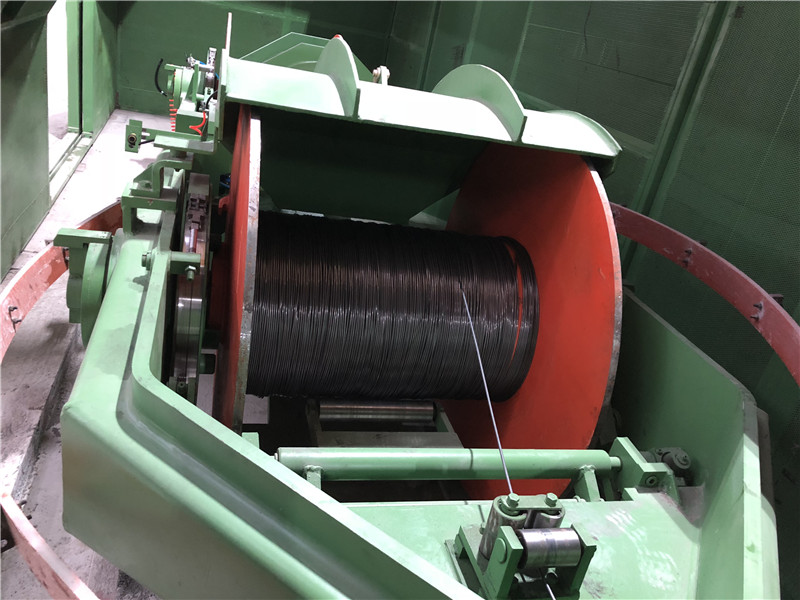

● Double spool take-up/pay-off (The first working as take-up and the second working as pay-off for rewinder)

|

Item |

Unit |

Specification |

|

Strand product size |

mm |

9.53; 11.1; 12.7; 15.24; 17.8 |

|

Line working speed |

m/min |

100m/min for 15.24mm |

|

Tension wheel diameter |

mm |

2200 |

|

Heating furnace power |

KW |

600 |

|

Heating temperature |

℃ |

370-420 |

|

Spool size of take-up and pay-off |

mm |

2700mm*1200mm*1400mm |

|

Rewinding speed |

m/min |

250 |

Product detail pictures:

Related Product Guide:

Our business puts emphasis over the administration, the introduction of talented staff, plus the construction of team building, attempting hard to boost the standard and liability consciousness of personnel customers. Our corporation successfully attained IS9001 Certification and European CE Certification of Super Lowest Price Wire Strand Processing Line - Prestressed Concrete (PC) Bow Skip Stranding Line PengSheng , The product will supply to all over the world, such as: Barbados, Moldova, San Diego, Immediate and expert after-sale service supplied by our consultant group has happy our buyers. Comprehensive Info and parameters from the merchandise will probably be sent to you for any comprehensive acknowledge. Free samples may be delivered and company check out to our corporation. n Morocco for negotiation is constantly welcome. Hope to get inquiries type you and construct a long-term co-operation partnership.

Cooperate with you every time is very successful, very happy. Hope that we can have more cooperation!

Write your message here and send it to us