Trending Products Glass Fiber Insulating Machine For Wire - Continuous Extrusion Machinery PengSheng

Trending Products Glass Fiber Insulating Machine For Wire - Continuous Extrusion Machinery PengSheng Detail:

Advantages

1, plastic deformation of feeding rod under the friction force and high temperature which eliminates the internal defects in the rod itself completely to ensure the final products with excellent product performance and high dimensional accuracy.

2, neither preheating nor annealing, good quality products gained by extrusion process with lower power consumption.

3, with a single size rod feeding, the machine could produce a wide size range of products by using different dies.

4, the whole line is easily and fast operated without any heavy work or pollution during extrusion.

Copper rod feeding

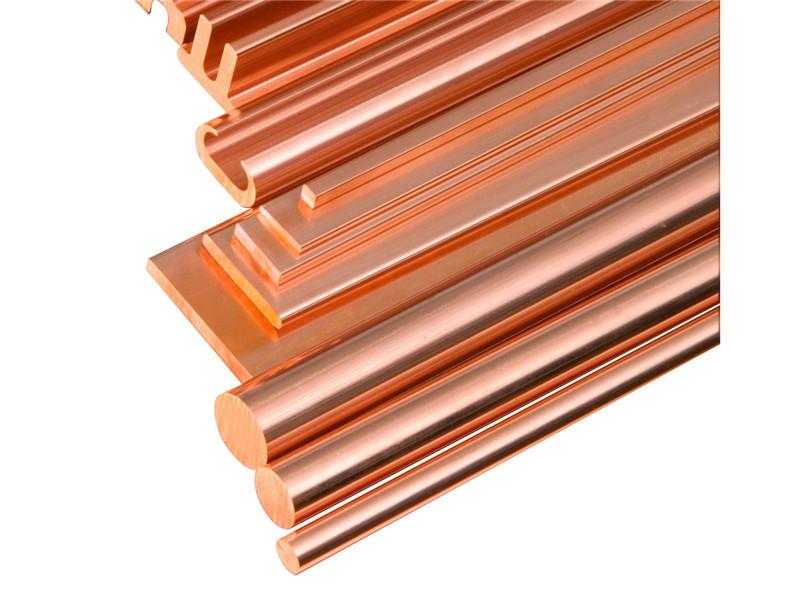

1.To make copper flat wires, small copper busbar and round wire

| Model | TLJ 300 | TLJ 300H |

| Main Motor Power(kw) | 90 | 110 |

| Feeding rod dia. (mm) | 12.5 | 12.5 |

| Max. width of product (mm) | 40 | 30 |

| Flat Wire Cross-Sectional | 5-200 | 5 -150 |

| Output(kg/h) | 480 | 800 |

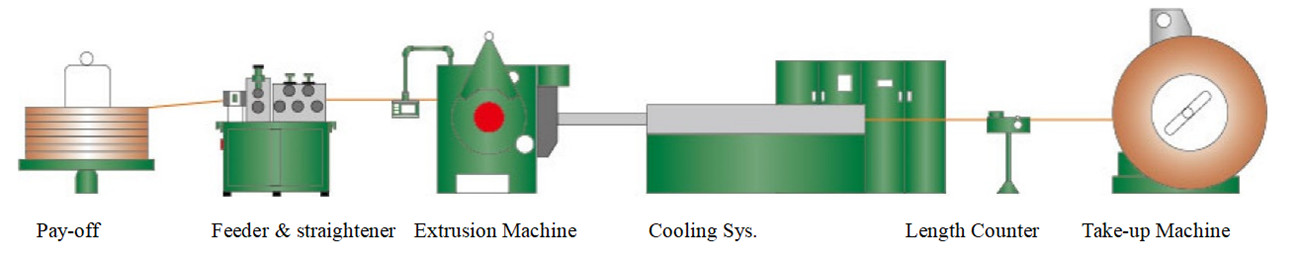

Production Line Layout

2.To make copper busbar, copper round and copper profile

| Model | TLJ 350 | TLJ 350H | TLJ 400 | TLJ 400H | TLJ 500 | TLJ 630 |

| main motor power(kw) | 160 | 200 | 250 | 315 | 355 | 600 |

| feeding rod dia. (mm) | 16 | 16 | 20 | 20 | 25 | 30 |

| max. width of product (mm) | 100 | 100 | 170 | 170 | 260 | 320 |

| product rod dia.(mm) | 4.5-50 | 4.5-50 | 8-90 | 8-90 | 12-100 | 12-120 |

| product cross-sectional area(mm2) | 15-1000 | 15-1000 | 75-2000 | 75-2000 | 300-3200 | 600-6400 |

| output(kg/h) | 780 | 950 | 1200 | 1500 | 1800 | 2800 |

Production Line Layout

3. To make copper busbar, copper strip

| Model | TLJ 500U | TLJ 600U |

| main motor power(kw) | 355 | 600 |

| feeding rod dia. (mm) | 20 | 30 |

| max. width of product (mm) | 250 | 420 |

| max. width to thickness ratio | 76 | 35 |

| product thickness(mm) | 3-5 | 14-18 |

| output(kg/h) | 1000 | 3500 |

Production Line Layout

Copper alloy rod feeding

Applying for commutator conductor, brass blank, phosphor copper rod, lead frame strip, railway contact wire etc.

| TLJ 350 | TLJ 400 | TLJ 500 | TLJ 630 | |

| material | 1459/62/63/65 brass cu/Ag (AgsO.08%) | phosphor copper (Pso.5%) cu/Ag (AgsO.3%) | magnesium copper (MgsO.5%)iron copper (Feso.l% | magnesium copper(MgsO.7%)/Cucrzr |

| feeding rod dia. (mm) | 12/12.5 | 20 | 20 | 25 |

| max. width of product (mm) | 30 | 150 (silver copper strip) | 100(lead frame strip:) | 320 |

| product rod dia.(mm) | phosphor copperball: 10-40 | magnesium copperrod: 20-40 | magnesium copperrod: 20-40 | |

| output(kg/h) | 380 | 800-1000 | 1000-1200 | 1250/850 |

Production Line Layout

Aluminum rod feeding

Applying for flat wire, bus bar, and profiled conductor, round tube, MPE, and PFC Tubes

| Model | LLJ 300 | LLJ 300H | LLJ 350 | LLJ 400 |

| main motor power(kw) | 110 | 110 | 160 | 250 |

| feeding rod dia. (mm) | 9.5 | 9.5 | 2*9.5/15 | 2*12/15 |

| max. width of flat wire product (mm) | 30 | 30 | 170 | |

| flat wire product cross-sectional Area(mm2) | 5-200 | 5-200 | 25-300 | 75-2000 |

| round tube dia. (mm) | 5-20 | 5-20 | 7-50 | |

| flat tube width(mm) | - | ≤40 | ≤70 | |

| flat wire /tube Output(kg/h) | 160/160 | 280/240 | 260/260 | (600/900)/- |

Production Line Layout

Product detail pictures:

Related Product Guide:

Our business aims to operating faithfully, serving to all of our clients , and working in new technology and new machine continuously for Trending Products Glass Fiber Insulating Machine For Wire - Continuous Extrusion Machinery PengSheng , The product will supply to all over the world, such as: Zimbabwe, Plymouth, Guatemala, We always insist on the management tenet of "Quality is First, Technology is Basis, Honesty and Innovation".We are able to develop new products continuously to a higher level to satisfy different needs of customers.

The quality of the products is very good, especially in the details, can be seen that the company work actively to satisfy customer's interest, a nice supplier.