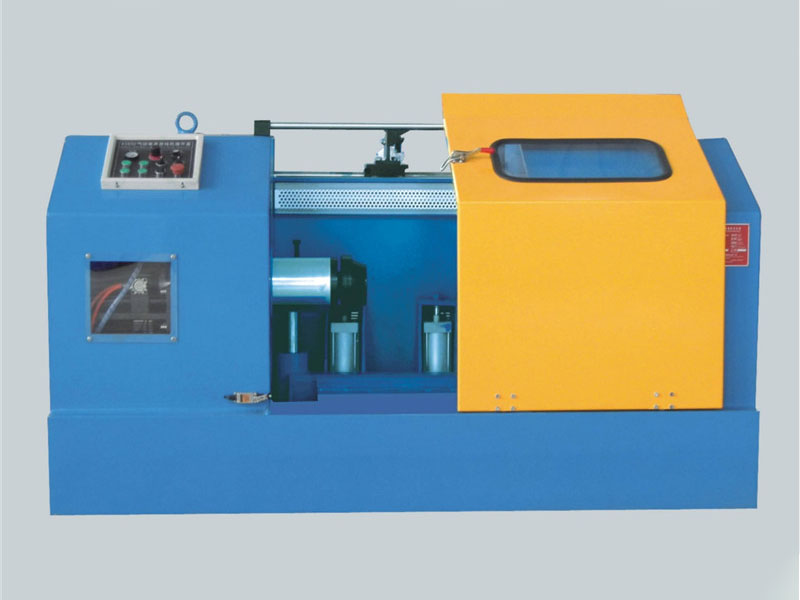

Wholesale Dealers of Prestressed Concrete Steel Wire Drawing Machine - Inverted Vertical Drawing Machine PengSheng

Wholesale Dealers of Prestressed Concrete Steel Wire Drawing Machine - Inverted Vertical Drawing Machine PengSheng Detail:

●High efficiency water cooled capstan & drawing die

●HMI for easy operation and monitoring

●Water cooling for capstan and drawing die

●Single or double dies / Normal or pressure dies

|

Block diameter |

DL 600 |

DL 900 |

DL 1000 |

DL 1200 |

|

Inlet wire material |

High/Medium/Low carbon steel wire; Stainless wire, Spring wire |

|||

|

Inlet wire Dia. |

3.0-7.0mm |

10.0-16.0mm |

12mm-18mm |

18mm-25mm |

|

Drawing speed |

According to the d |

|||

|

Motor power (For reference) |

45KW |

90KW |

132KW |

132KW |

|

Main bearings |

International NSK, SKF bearings or customer required |

|||

|

Block cooling type |

Water flow cooling |

|||

|

Die cooling type |

Water cooling |

|||

Product detail pictures:

Related Product Guide:

We emphasize enhancement and introduce new solutions into the market just about every year for Wholesale Dealers of Prestressed Concrete Steel Wire Drawing Machine - Inverted Vertical Drawing Machine PengSheng , The product will supply to all over the world, such as: Saudi Arabia, Curacao, Zurich, We confirm to public, cooperation, win-win situation as our principle, adhere to the philosophy of make a living by quality, keep developing by honesty , sincerely hope to build up a good relationship with more and more customers and friends, to achieve a win-win situation and common prosperity.

Goods just received, we are very satisfied, a very good supplier, hope to make persistent efforts to do better.

Write your message here and send it to us