Wholesale Flat Conductor Taping Machine - Fiber Glass Insulating Machine PengSheng

Wholesale Flat Conductor Taping Machine - Fiber Glass Insulating Machine PengSheng Detail:

Main technical data

Round conductor diameter: 2.5mm—6.0mm

Flat conductor area: 5mm²—80 mm²(Width: 4mm-16mm, Thickness: 0.8mm-5.0mm)

Rotating speed: max. 800 rpm

Line speed: max. 8 m/min.

Special Characteristics

Servo drive for the winding head

Auto-stop when fiberglass broken

Rigid and modular structure design to eliminate vibration interaction

PLC control and touch screen operation

Overview

Taping

Oven

Product

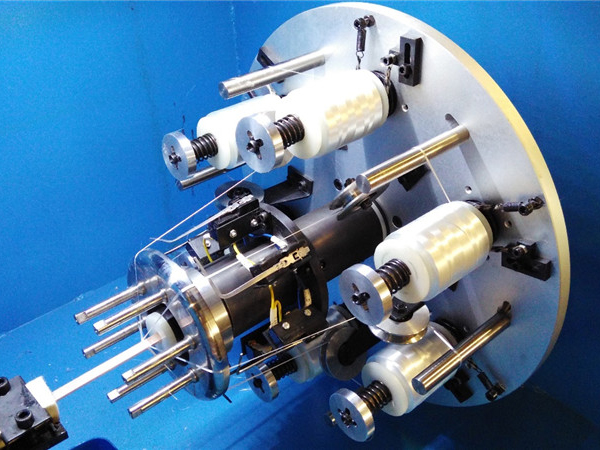

Product detail pictures:

Related Product Guide:

We constantly continually give you essentially the most conscientious client provider, plus the widest variety of designs and styles with finest materials. These initiatives include the availability of customized designs with speed and dispatch for Wholesale Flat Conductor Taping Machine - Fiber Glass Insulating Machine PengSheng , The product will supply to all over the world, such as: Honduras, Japan, Accra, Certainly, competitive price, suitable package and timely delivery will be assured as per customers' demands. We sincerely hope to build business relationship with you on the basis of mutual benefit and profit in the very near future. Warmly welcome to contact us and become our direct cooperators.

This company has a lot of ready-made options to choose and also could custom new program according to our demand, which is very nice to meet our needs.

Write your message here and send it to us