Wholesale Price China Magnet Wire Paper Taping Machine - Combined Taping Machine – Multi Conductors PengSheng

Wholesale Price China Magnet Wire Paper Taping Machine - Combined Taping Machine – Multi Conductors PengSheng Detail:

Main technical data

Single wire quantity: 2/3/4 (or customized)

Single wire area: 5 mm²—80mm²

Rotating speed: max. 1000 rpm

Line speed: max. 30 m/min.

Pitch accuracy: ±0.05 mm

Taping pitch: 4~40 mm, step less adjustable

Special Characteristics

-Servo drive for the taping head

-Rigid and modular structure design to eliminate vibration interaction

-Taping pitch and speed easy adjusted by touch screen

-PLC control and touch screen operation

Overview

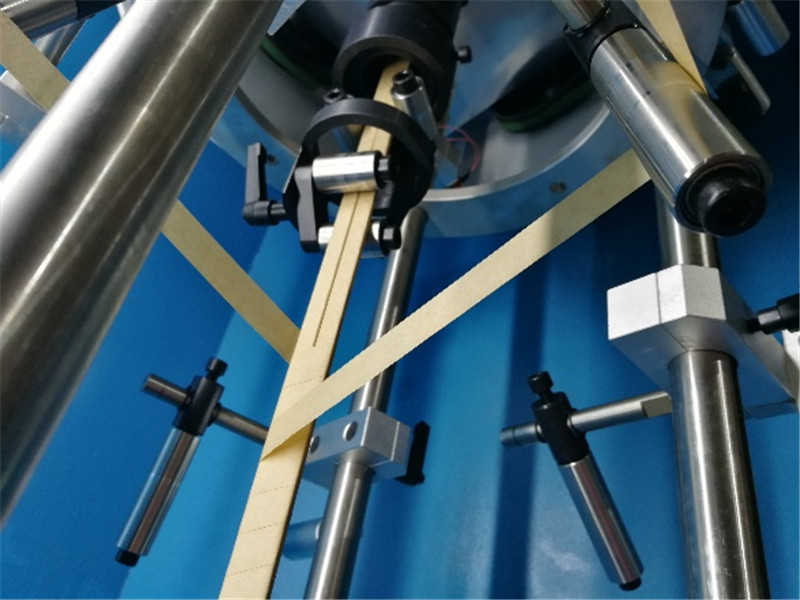

Taping

Caterpillar

Take-up

Product detail pictures:

Related Product Guide:

Assume full responsibility to meet all demands of our clients; achieve continuous advancements by promoting the growth of our clients; become the final permanent cooperative partner of clients and maximize the interests of clients for Wholesale Price China Magnet Wire Paper Taping Machine - Combined Taping Machine – Multi Conductors PengSheng , The product will supply to all over the world, such as: Iraq, Swansea, Ghana, Our products have enjoyed a great reputation for their good quality, competitive prices and prompt shipment in international market. Presently, we are sincerely looking forward to cooperating with more overseas customers based on mutual benefits.

This enterprise in the industry is strong and competitive, advancing with the times and develop sustainable, we are very pleased to have a opportunity to cooperate!

Write your message here and send it to us