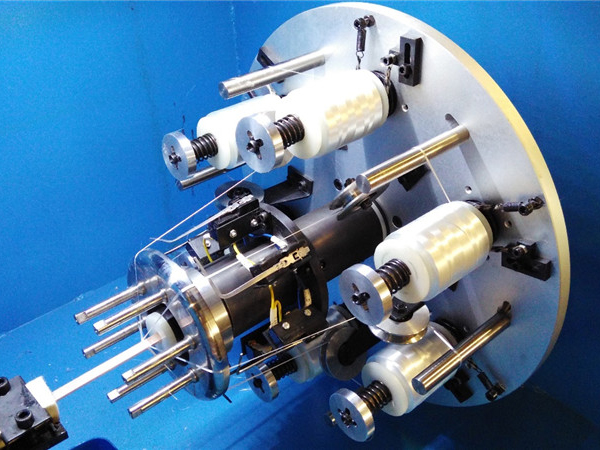

Wholesale Price China Magnet Wire Paper Taping Machine - Fiber Glass Insulating Machine PengSheng

Wholesale Price China Magnet Wire Paper Taping Machine - Fiber Glass Insulating Machine PengSheng Detail:

Main technical data

Round conductor diameter: 2.5mm—6.0mm

Flat conductor area: 5mm²—80 mm²(Width: 4mm-16mm, Thickness: 0.8mm-5.0mm)

Rotating speed: max. 800 rpm

Line speed: max. 8 m/min.

Special Characteristics

Servo drive for the winding head

Auto-stop when fiberglass broken

Rigid and modular structure design to eliminate vibration interaction

PLC control and touch screen operation

Overview

Taping

Oven

Product

Product detail pictures:

Related Product Guide:

We now have a highly efficient crew to deal with inquiries from clients. Our intention is "100% shopper pleasure by our merchandise quality, price tag & our staff service" and take pleasure in a very good standing amongst purchasers. With quite a few factories, we can easily provide a wide vary of Wholesale Price China Magnet Wire Paper Taping Machine - Fiber Glass Insulating Machine PengSheng , The product will supply to all over the world, such as: Guatemala, Stuttgart, Albania, So We also continuously function. we, focuse on high quality, and are conscious of the importance of environmental protection, most of the merchandise are pollution-free, environmentally friendly products, reuse on the solution. We've Updated our catalog, which introduces our organization. n detail and covers the primary items we provide at present, You may also visit our web-site, which involves our most recent product line. We look forward to reactivating our company connection.

This is a very professional wholesaler, we always come to their company for procurement, good quality and cheap.

Write your message here and send it to us