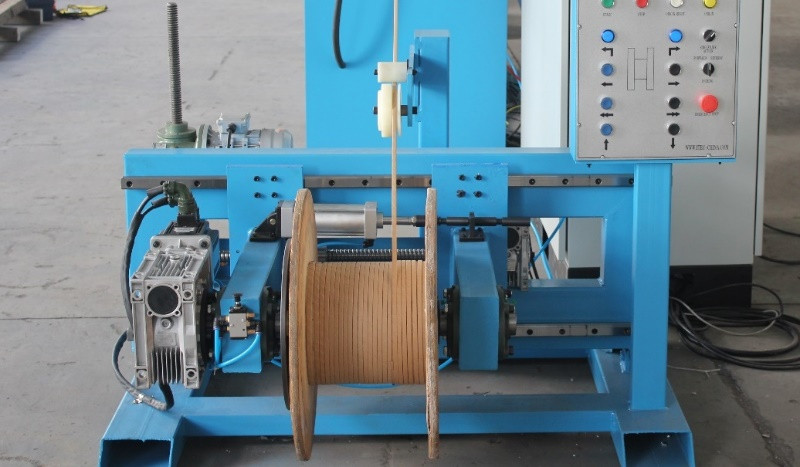

Wholesale Price China Magnet Wire Paper Taping Machine - Horizontal Taping Machine-Single Conductor PengSheng

Wholesale Price China Magnet Wire Paper Taping Machine - Horizontal Taping Machine-Single Conductor PengSheng Detail:

Main technical data

Conductor area: 5 mm²—120mm²(or customized)

Covering layer: 2 or 4 times of layers

Rotating speed: max. 1000 rpm

Line speed: max. 30 m/min.

Pitch accuracy: ±0.05 mm

Taping pitch: 4~40 mm, step less adjustable

Special Characteristics

-Servo drive for the taping head

-Rigid and modular structure design to eliminate vibration interaction

-Taping pitch and speed easy adjusted by touch screen

-PLC control and touch screen operation

Overview

Taping head

Caterpillar

Take-up

Product detail pictures:

Related Product Guide:

We depend on sturdy technical force and continually create sophisticated technologies to meet the demand of Wholesale Price China Magnet Wire Paper Taping Machine - Horizontal Taping Machine-Single Conductor PengSheng , The product will supply to all over the world, such as: Nepal, Montreal, Gabon, We have now a good reputation for stable quality goods, well received by customers at home and abroad. Our company would be guided by the idea of "Standing in Domestic Markets, Walking into International Markets". We sincerely hope that we could do business with car manufacturers, auto part buyers and the majority of colleagues both at home and abroad. We expect sincere cooperation and common development!

The goods we received and the sample sales staff display to us have the same quality, it is really a creditable manufacturer.

Write your message here and send it to us