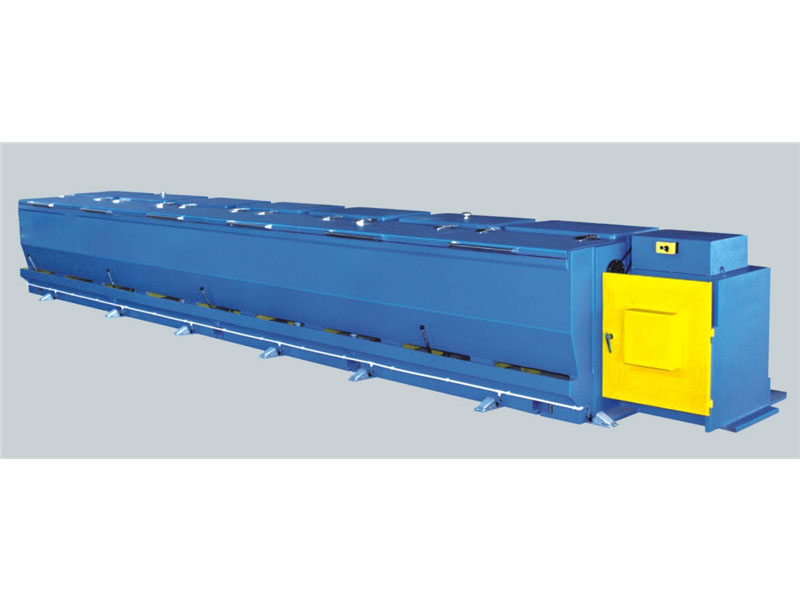

Wire and Cable Laser Marking Machine

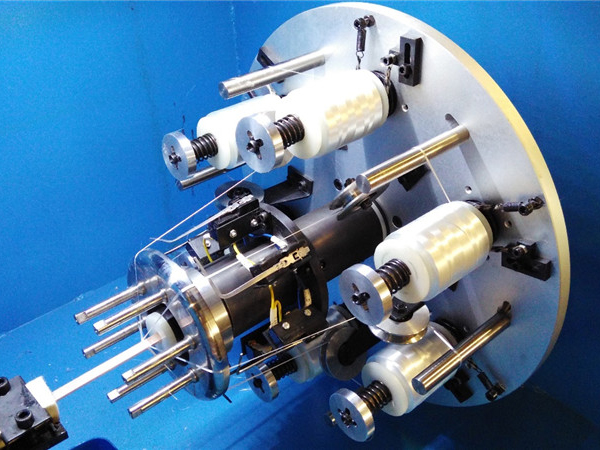

Working Principle

The laser marking device detects the pipeline speed of the pipe by the speed measuring device, and the marking machine realizes dynamic marking according to the pulse change marking speed fed back by the encoder.The interval marking function such as wire rod industry and software implementation, etc., can be set by software parameter setting. There is no need for photoelectric detection switch for flight marking equipment in wire rod industry. after one trigger, the software automatically realizes multiple marking at equal intervals.

U Series-Ultra Violet (UV) Laser Source

| HRU Series | |||

| Applicable Material & Color | Most of the material & colorPVC, PE, XLPE, TPE, LSZH, PV, PTFE, YGC, Silicone Rubber etc,. | ||

| Model | HRU-350TL | HRU-360ML | HRU-400ML |

| Marking Speed(M/min) | 80m/min | 100m/min | 150m/min |

| Compatibility (General mark speed based on content) |

400m/min(Wire number ) | 500m/min(Wire number ) | |

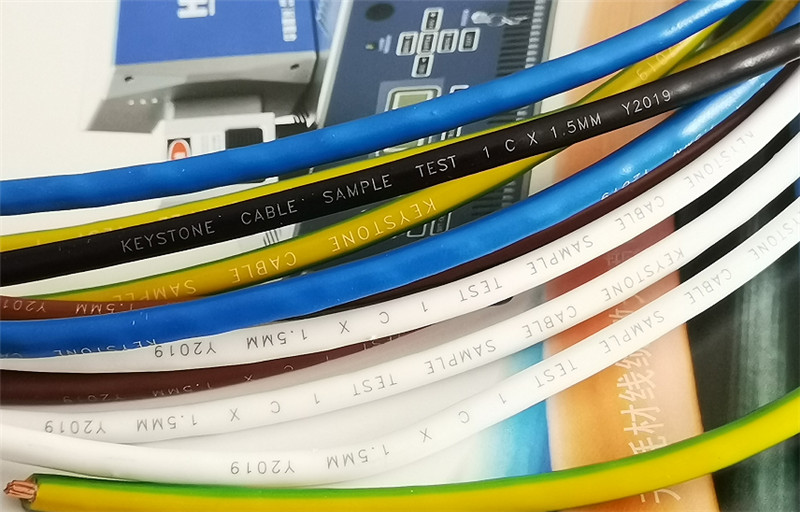

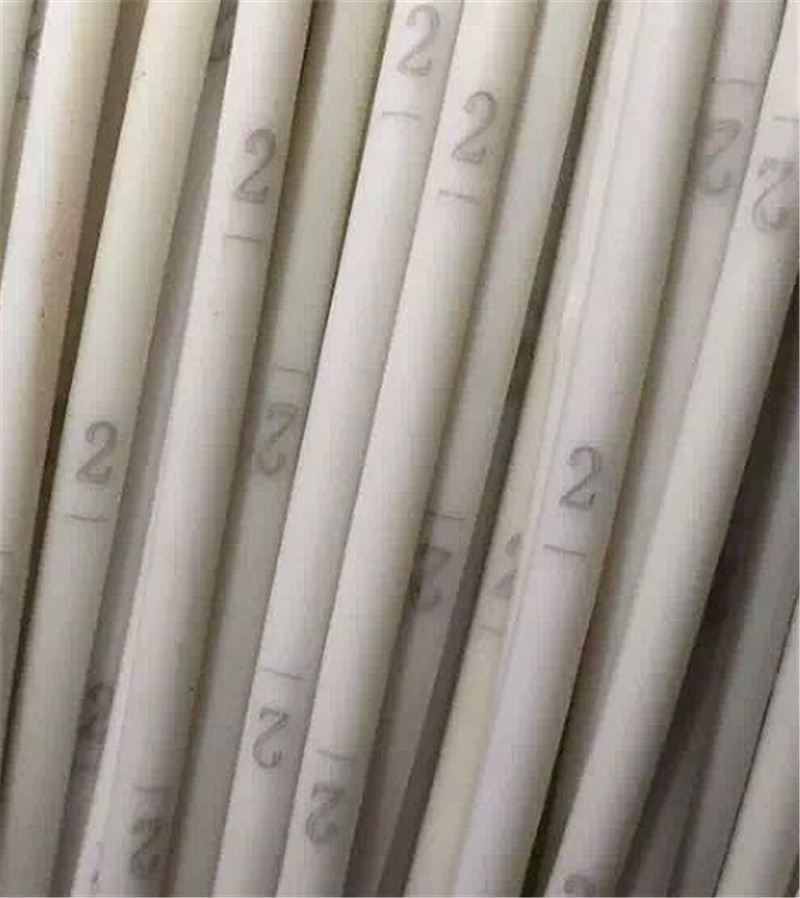

U Series Marking Effect

G Series -Fiber Laser Source

| HRG Series | ||||

| Applicable Material & Color | Black insulator sheath, BTTZ/YTTW. PVC,PE,LSZH,PV,PTFE,XLPE.Aluminum.Alloy.Metal.Acrylics, etc,. | |||

| Model | HRG-300L | HRG-500L | HRG-300M | HRG-500M |

| Marking Speed(M/min) | 80m/min | 120m/min | 100m/min | 150m/min |

| Compatibility(General mark speed based on content) | 400m/min (Wire number ) |

500m/min(Wire number ) | ||

G Series Marking Effect

C Series- Carbon Dioxide (Co2) Laser Source

| HRC Series | |||

| Applicable Material & Color | PVC (Various color), LSZH (Orange/Red), PV (Red), TPE (Orange), Rubber etc,. | ||

| Model | HRC-300M | HRC-600M | HRC-800M |

| Marking Speed(M/min) | 70m/min | 110m/min | 150m/min |

C Series Marking Effect

Write your message here and send it to us